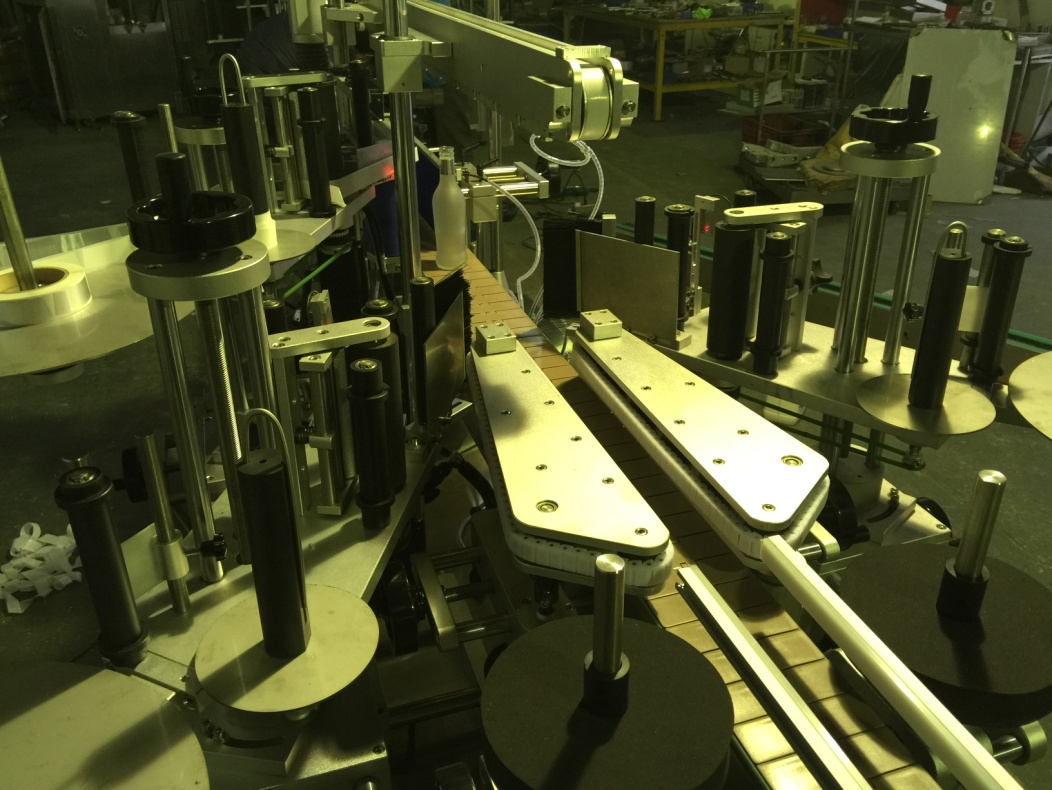

TB-3-3000 3-Sides Labeling Machine

Features:

With innovative & patented technology applied in the machine with the use of highly reliable motor, controlled in a feedback loop using PLC under the command of user friendly touch screen based human interface, the label feed rate can be changed in steps of 0.01m/min. This leads to 100 times more accurate performance compared to other labeling machines made in China, which are still at step of 1m/minute while changing the label feed rate.

The line conveyor is driven by high-power imported AC motor with an inverter based speed control ensure stable conveying of bottles, thus further enhancing labeling precision.

Exclusively applies elastic macromolecule overhead pressing belt and gear in the main transmission system, making sure they’re absolutely kept in synchronism. Also solid structure of the overhead belt prevents product sway while labeling.

The position of product sensor in the machine is adjustable, making it possible to realize zero delay. This greatly increases labeling accuracy. In most of other labeling machines, product sensor is not adjustable hence use delay control instead leading to compromise with labeling accuracy. Variation in operating voltages or change in load on transmission system will lead to big labeling offset in such cases.

Product clamping unit

The machine incorporates specially designed nylon chain with smooth surface to clamp the product flatly & exactly without any scratch. With total four fix points, the offset is less than ±0.5 mm.

Product separator unit

Sunswell machine employs couple of opposite rotating sponge rollers on either sides of the line and can be set to run at different speed then that of the conveyor speed resulting in separation of products. This method is of good effect and can be easily applied in many situations. No need of replacement when product changes.

Label applicator can be adjusted on 6 different axis because of which one can freely adjust labeling position and angle. This is especially valuable when labeling difficult transparent label on a variety of profiles of product surfaces.

Combination of elastic label flap + passive sponge rollers’ 1st press + active sponge rollers; 2nd press makes sure no air bubble or wrinkle occurred while labeling.

Technical Parameter:

Servo system control

Capacity: 3,000BPH (500ml) for 3 labels

Label feeding speed: 35m/min (0-80BPM) subject to label size

Labeling accuracy: ±1mm

Label max width: 200mm

Bottle size: Thickness ≤88mm; height≤460mm

Label size: width 15-150mm, length 15-300mm

Label inner diameter: φ76mm

Label outer diameter: Max φ350mm

Machine size: 2800*1350*1500mm

Power: 220V 50Hz 1.5kw

Weight: 500kg

Air pressure: at least 5pa

Specifications:

|

Denomination |

Model |

Qty. |

Brand |

Origin |

|

PLC |

FX-20MT |

1 |

Mitsubishi |

Japan |

|

Touch screen |

TK6070-IK |

1 |

WEINVIEW |

Taiwan, China |

|

Photoelectric sensor |

FX-301 |

8 |

Panasonic |

Japan |

|

Servo motor |

BCH08012AIC |

3 |

Panasonic |

Japan |

|

Servo motor drive |

SErvodrive750w |

3 |

Schneider |

France |

|

Inverter |

BFV00022DK |

3 |

Panasonic |

Japan |

|

Bottle Separating Motor |

4GN-25W-65K |

1 |

Adlee |

Taiwan, China |

|

Conveyor Inverter |

BFV00022DK |

1 |

Panasonic |

Japan |

|

Conveyor Motor |

RV50-20-0.75KW |

1 |

Adlee |

Taiwan, China |

|

Switch Button |

XB2-BD21 |

1 |

Schneider |

France |

|

Switch Power |

S-35-24 |

1 |

MW |

Taiwan, China |

|

AC Contactor |

LC1-D1810M5C |

1 |

Shangmin |

China |

|

Breaker |

DZ47-36 |

1 |

Shangmin |

China |

|

Discharge Fan |

SF11025AT |

1 |

Luann |

Shanghai |

|

Pneumatic Cylinder |

SDAS32*25 |

2 |

Airtac |

Taiwan, China |