Combiblock – Blowing - Filling & Capping For juice - tea and energy drinks by ultra-clean or hot filling

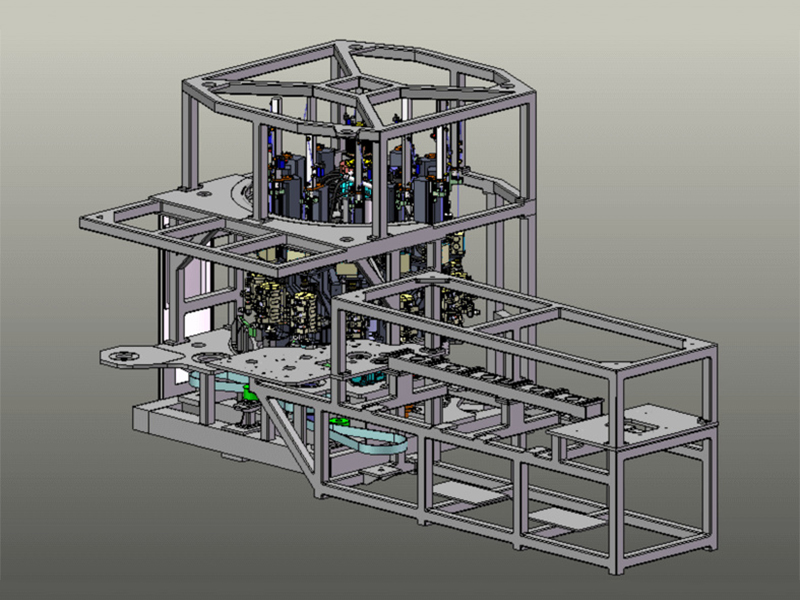

3-in-1 combiblock, composed of blowing, ultra clean or hot filling and capping. It is innovated and designed in the requirement of carbonated soft drinks and carbonated water. The combiblock avoids friction of bottles during air conveying.

Capacity: 12,000 – 36,000BPH (500ml)

Features

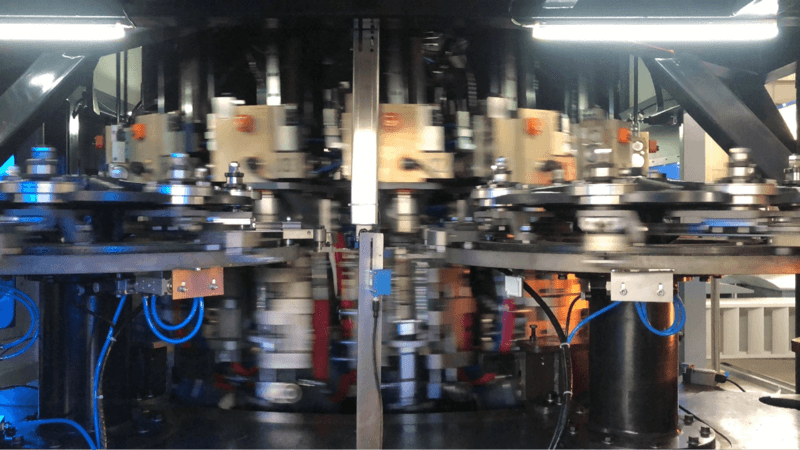

Rotary Blow Molding Machine

1) Horizontal heating chain drive system

♦ Use high-strength brass processing to extend the service life

♦ Large caliber cooling mouth, to ensure that the preform neck not heated, with effective protection of preform thread

2) Efficient energy-saving preform heating system

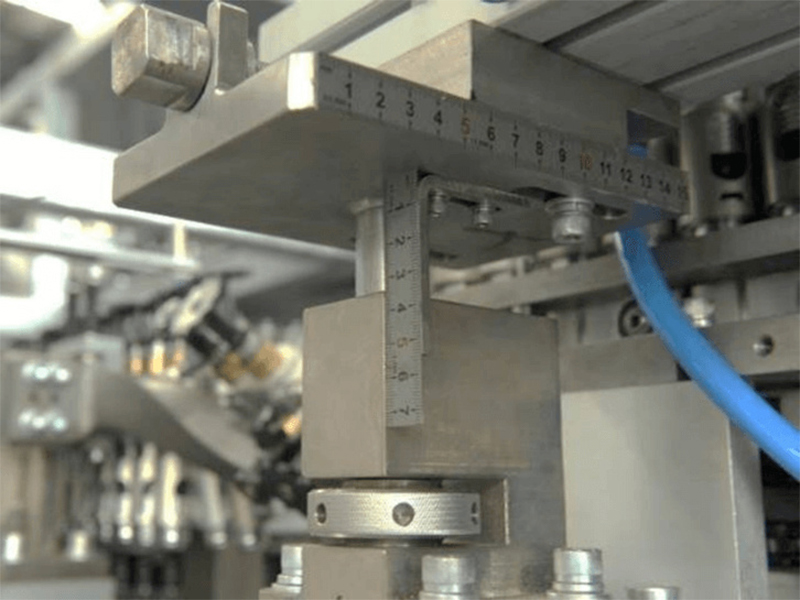

♦ Adjustment device with ruler instructions, equipment adjustment more convenient

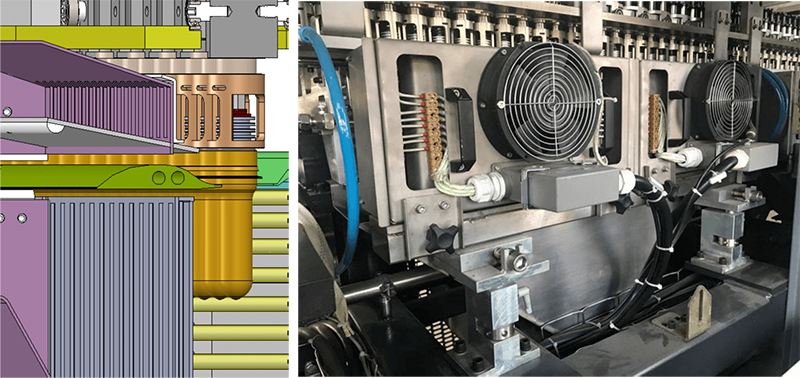

♦ Using streamlined guide plate, so that the air flow more effectively on the preform neck cooling and protection

♦ Mirror reflector, high reflection, more energy efficient

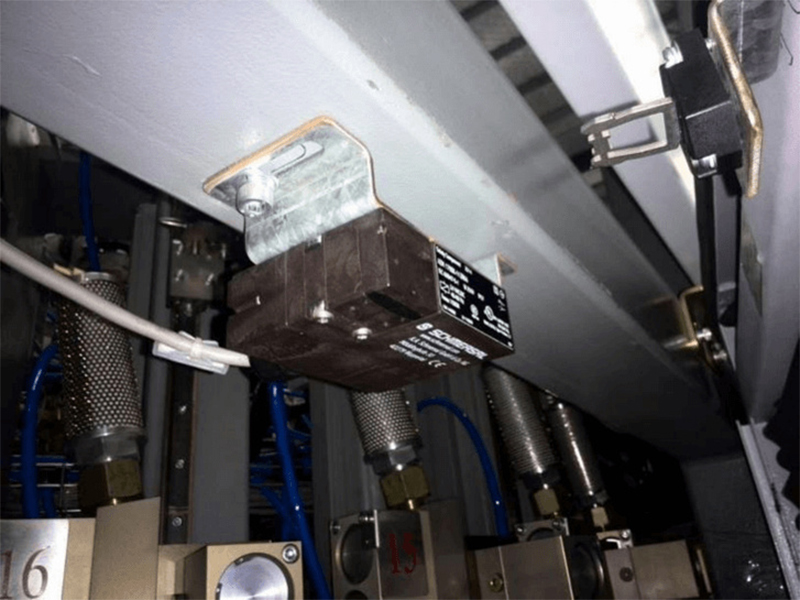

♦ Norgren’s smaller high pressure valve group, less dead space

♦ Saving blowing air

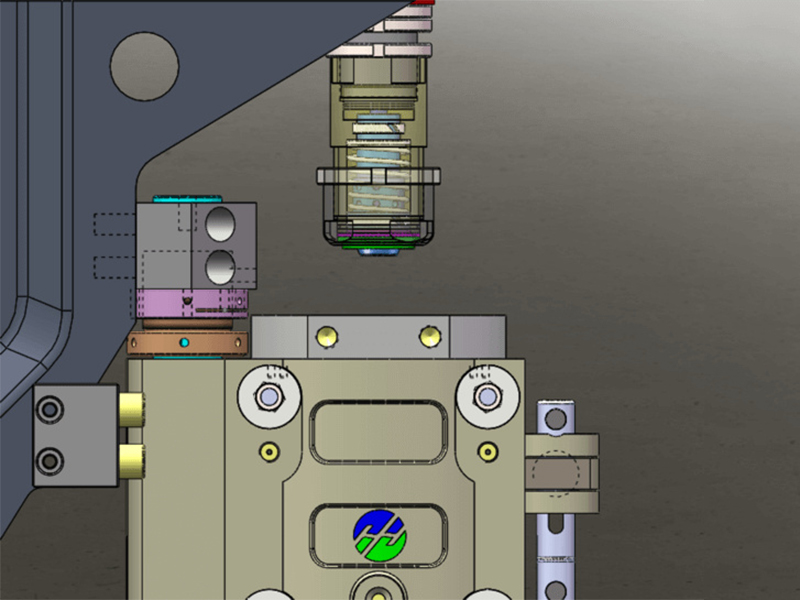

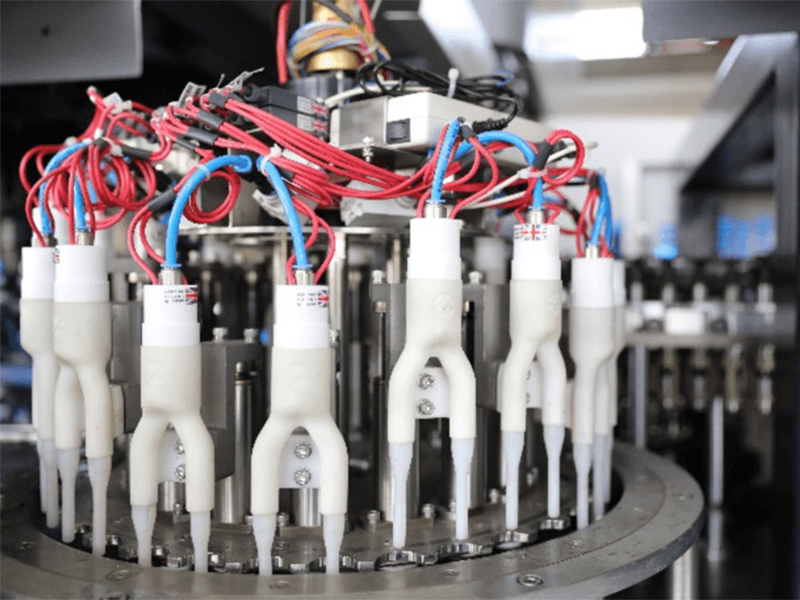

3) Patented blowing nozzle unit for stable preform

♦ Positioning first, sealing after, to ensure that the preform vertical blowing, more stable.

♦ To avoid broken bottle blocking machine phenomenon.

4) Fast mold changing unit (6-screw design)

♦6-screw mold change design

♦ 6-8min for each mold changing

5) H-type steel frame, reducing vibration, more stable

♦ Driving platen and the host frame as a whole processing, more accurate to feed preforms. Ensure without vibration at 2000BPH each cavity.

♦ H-type steel welding, high-speed rotation more stable.

6) High accurate filtration system and High pressure air recycling system

♦ High-pressure air recovery system can save 30% of air, in addition, the extra gas leads to other machines.

♦ High-pressure filtration system accuracy of 0.001ppmw, greatly extend the service life of pneumatic components.

7) High speed & energy saving blowing system

♦Integrated brake system with slewing ring, more reliable and stable.

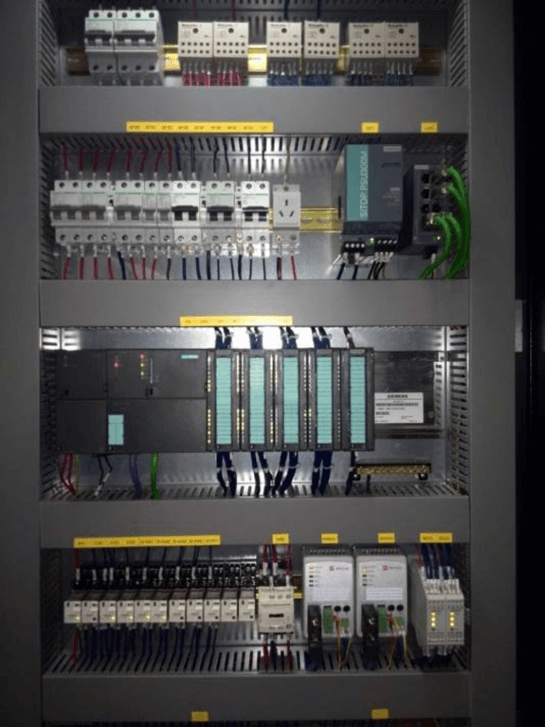

8) Reliable electrical control

♦ Through the teleservice remote monitoring system, real-time recording of any operation of the field device or shutdown information, through the analysis of software real-time analysis of equipment operating status.

♦ Safety relay equipped

♦ Safety door locking

9) Air conditioning and Anti-condensation System on electrical cabinet

10) Ion air blowing

♦ Ion gas blowing for removing dust on preform

♦ Positive and negative ion generator neutralize static electricity on surface of preform

♦ Blow clean compressed air onto the surface of the preform

♦ Vacuum dust suction

Rotary Ultra-clean / Hot filling machine

The design of filling structure is reasonable and hygiene dead angle, the run of equipment is stable, it can control the material from the bottleneck, the control accuracy is within ±2mm.

The filling valve material is SUS304

The filling system has liquid level automatic control.

Filling valve lift is controlled by the valve elevator, after filling valve contact the bottleneck ,it start to fill.

Bottle is conveying by the wheel in the filling part.

The juice or other hot beverage can be backflow by return tank to control filling temperature.

Capping Machine

a) Magnetic constant torque capping head ensures stability and controls defective rate of capping less than 0.2%.

b) Cap dropping rail equips a group of photoelectrical switch for reverse cap detecting. When lack of cap, machine will be stopped automatically.

c) Bottle infeed detecting switch works with the pneumatic cylinder on cap starwheel to avoid feeding cap on no-bottle condition.

Equipment Structure

♦ Stand

♦ Rotary blow molder

♦ Rotary filler

♦ Rotary capper

♦ Bottle infeed and outfeed system

♦ Control