Zipper closure

1/5 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the

body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them

in

place during workout

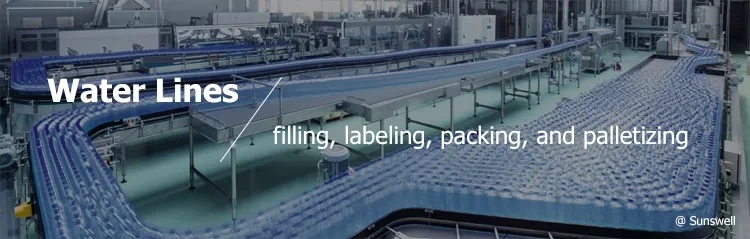

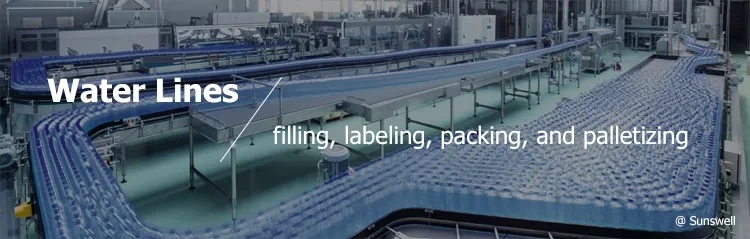

Sunswell - Water Production Line

We all know that success in water beverage production requires focus on maximum output and efficiency, with commitment to hygiene, food safety and cost optimization.

With over 10 years of experience in designing and implementing customized complete PET and glass line solutions for water, sunswell can help you reach your production targets from water treatment,blowing, filling, labeling, packing, and palletizing up to and including inspection and complete sanitizing.

We can produce pure water ,mineral water, drinking water, soda water, flavored water , natural water ,spring water ,potable

water, flavoured water. Depending on the different packages, we can divide it into two categories: bottled mineral water line(200ml-2000ml) and barreled mineral water line (1- 5 gallon water line).

The following are the main types of bottles we have been exposed to in the past, from the most common plastic bottles, gallon drums to glass bottles and cans, and we all have a successful complete solution.

Turnkey/complete water production line includes :

1. Bottle blowing system make PET plastic bottles ( Semi automatic / Fully automatic )

2. Water treatment system purify water (Sand filter,carbon filter,RO/UF ,Ozone sterilizer,UV sterilizer and etc.)

3. Air conveyor for empty bottle loading

4. Rinser-filler-capper 3 in 1 monoblock

5. Cap loader load caps

6. Code printer (Ink-jet printer/ laser-jet printer)

7. Labeling machine ( PVC sleelve labeling machine/OPP hot melt glue labeling machine/Self-adheisive labeling machine )

8. End packaging ( PE shrink wrapping machine / Carton packing machine )

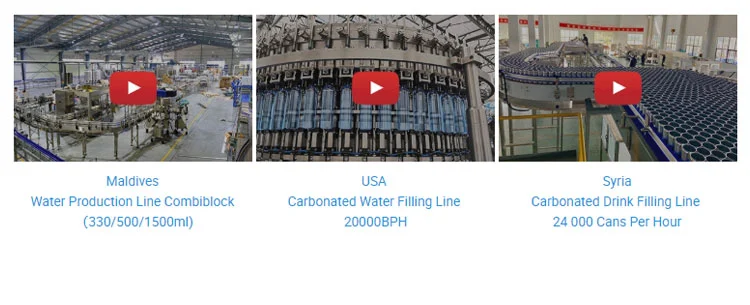

Some complete water bottling line projects delivered include:

Water Filling Machine

The water filling machine is consisted of ringsing-filling-caping all together. CGF water filling machine adpots the suspension design. It allows the machine to fill different type of the bottles. It is normally used as drinking water filling machine. However, it can also be used for fill PET bottle with fruit juice and tea at high temperature by simply change tha valve. It can be connected with our others machines to form the water filling machine and packaging machinery production line.

Equipment structure:1. Rinsing system: Combined with rotary tray with clamp, water distributing tray, water tank and rinsing pump. 2. Filling system: Combined with hydraulic, filling valve, controlling ring, and elevator-cylinder. 3. Capping system: Combined with capper, cap sorter and cap falling track. 4. Driving system: Combined with main motor and gears. 5. Bottle transmitting system: Combined with air conveyor, steel starwheels and neck supporting carrier plates. 6. Electrical controlling system: this part is frequency inverted, PLC controlled and touch screen operated.

|

Model

|

CGF12125

|

CGF18186

|

CGF24248

|

CGF323210

|

CGF404012

|

CGF505012

|

|

washing, filling and capping heads

|

12-12-5

|

18-18-6

|

24-24-8

|

32-32-10

|

40-40-12

|

50-50-12

|

|

Production capacity(600ml)

(B/H)

|

2000-4000

|

5000-7000

|

8000-12000

|

12000-15000

|

16000-20000

|

20000-24000

|

|

Motor power(kw)

|

2.2kw

|

2.2kw

|

3kw

|

5.5kw

|

7.5kw

|

11kw

|

|

Weight (kg)

|

2500

|

3500

|

4500

|

6500

|

8500

|

9800

|

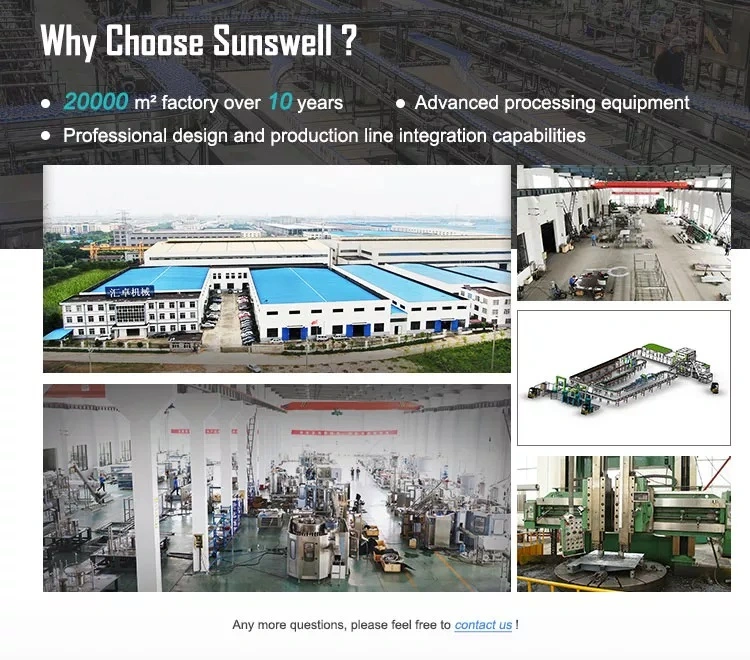

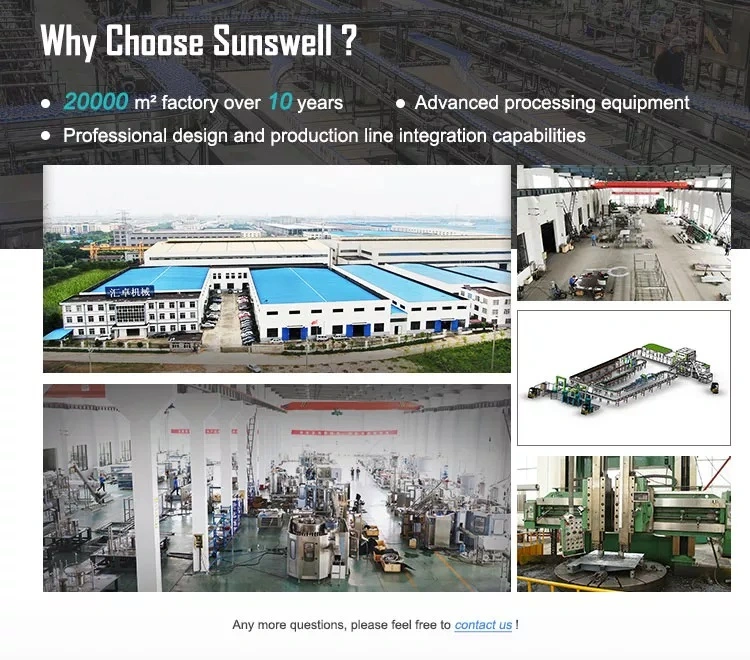

About Sunswell:

Set up in 2008, Sunswell leads the market in the field of liquid bottling, blow molding, labeling, packaging machinery and process technology for water, tea, juice, carbonated drinks, energy drinks, liquid, beer, edible oil, dairy and daily care products, etc.

Advantage:

(1)A to Z turnkey plant provider (2)Fully automatic or economic solution optional (3)10+ years of global market experience (4)Serve customers over 50 countries and regions worldwide

About Sunswell:

Set up in 2008, Sunswell leads the market in the field of liquid bottling, blow molding, labeling, packaging machinery and process technology for water, tea, juice, carbonated drinks, energy drinks, liquid, beer, edible oil, dairy and daily care products, etc.

Advantage:

(1)A to Z turnkey plant provider (2)Fully automatic or economic solution optional (3)10+ years of global market experience (4)Serve customers over 50 countries and regions worldwide