Fully Automatic aluminum can depalletizer

For various metal cans, glass bottles, plastic bottles for layered depalletizing.

Feature:

1.The machine is suitable for automatic depalletizing for piles of tinplate empty can.

2.It lifts empty can on the the pallets from bottom to top,and push to the conveyor layer by layer,use together with the empty can spray washer,replace manual can arrangement.

3.traditional empty can unloader,save a lot of manpower and inclease production capacity.

4.The pile feeding direction,can-out direction,operation table all could be set according to the user's requirement.

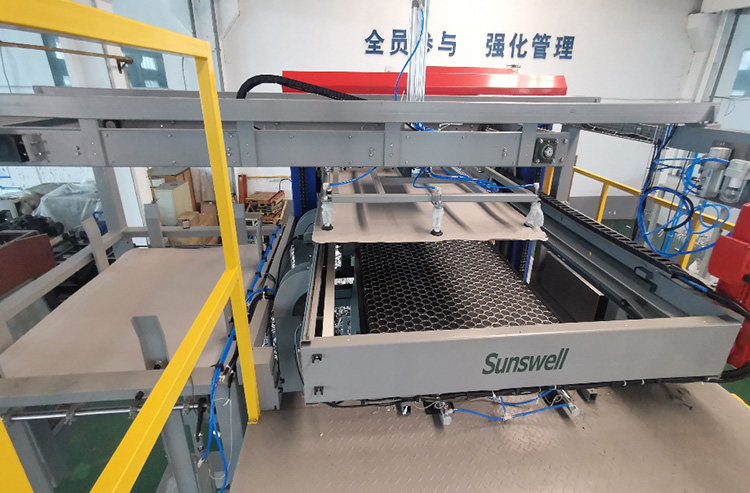

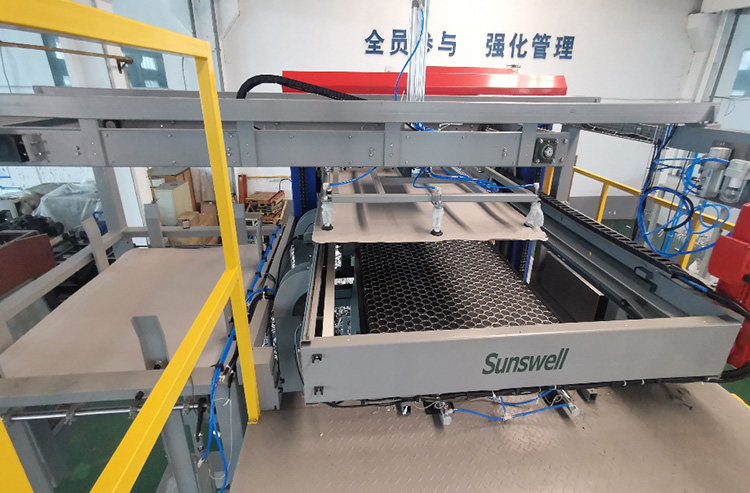

Machinery Structure

Full pallet conveyor, pallet life device, whole layer cans pushing trolly, isolate remover, empty pallet stacker.

-

Pallet stacker

-

Isolate pad pneumatic mover

-

Four sides cylinder clamp holder

Advantages

1. High performing

2. Reliable

3. Flexible (in terms of container, format and pallet)

4. Quick and easy format changeover

5. Completely automated

6. Fully customizable

7. High operator safety standards

Appliance scope

For various metal cans, glass bottles, plastic bottles for layered depalletizing.

Depalletizer workflow and principles

1. Forklift put the whole stack cans/bottles into unstacking station (hydraulic lift table)

2. Chain lifter will transit the packed pallet to the upper most of the depalletizer.

3. Four sides clamps will hold the uppermost whole layer cans or bottles from four sides, moving in parallel to the outlet multi lane conveyor.

4. The the four sides cylinder clamps will back to original position.

5. Pneumatic absorb hands will absorb the next layer top side isolate pad, move the pad to pad collector.

6. Chain lifter, hold the board rise to a certain height crib.

7. Do the same procedure until the last layer, hydraulic lifts pallet fell to bottom, then transit to empty pallets stacker.

8. Forklift remove the empty pallet.

Specification

|

Item |

Brand |

|

PLC |

Siemens/Mitsubishi/Schneider/Delta |

|

Motor |

SEW/ABB/Siemens/Tongyu/Nord/Weg/Jie |

|

Pneumatic control |

Airtac/Festo/SMC |

|

Low volts component |

Schneider/Siemens/Chintai/Delixi |

Technical parameters

Model: XD600

Capacity: 36000CPH (330ml)

Feed adjustable: +/-50mm

Platform: carbon steel

Conveyor height: 3100mm

Pallet height: 2800mm

Workshop height: 4500mm

Empty pallet stacker: ten pallets

Pallet size: L1420mm*W1120mm*H150mm (customized)

Overall dimension: L5800mm*W1350mm*H3700mm

Weight: 3700kg

Power

Power supply: 380V, 50Hz, 3PH

Total power: 2.05KW

Main motor: 0.75KW

Can conveyor motor 1: 0.75KW

Can conveyor motor 2: 0.75KW