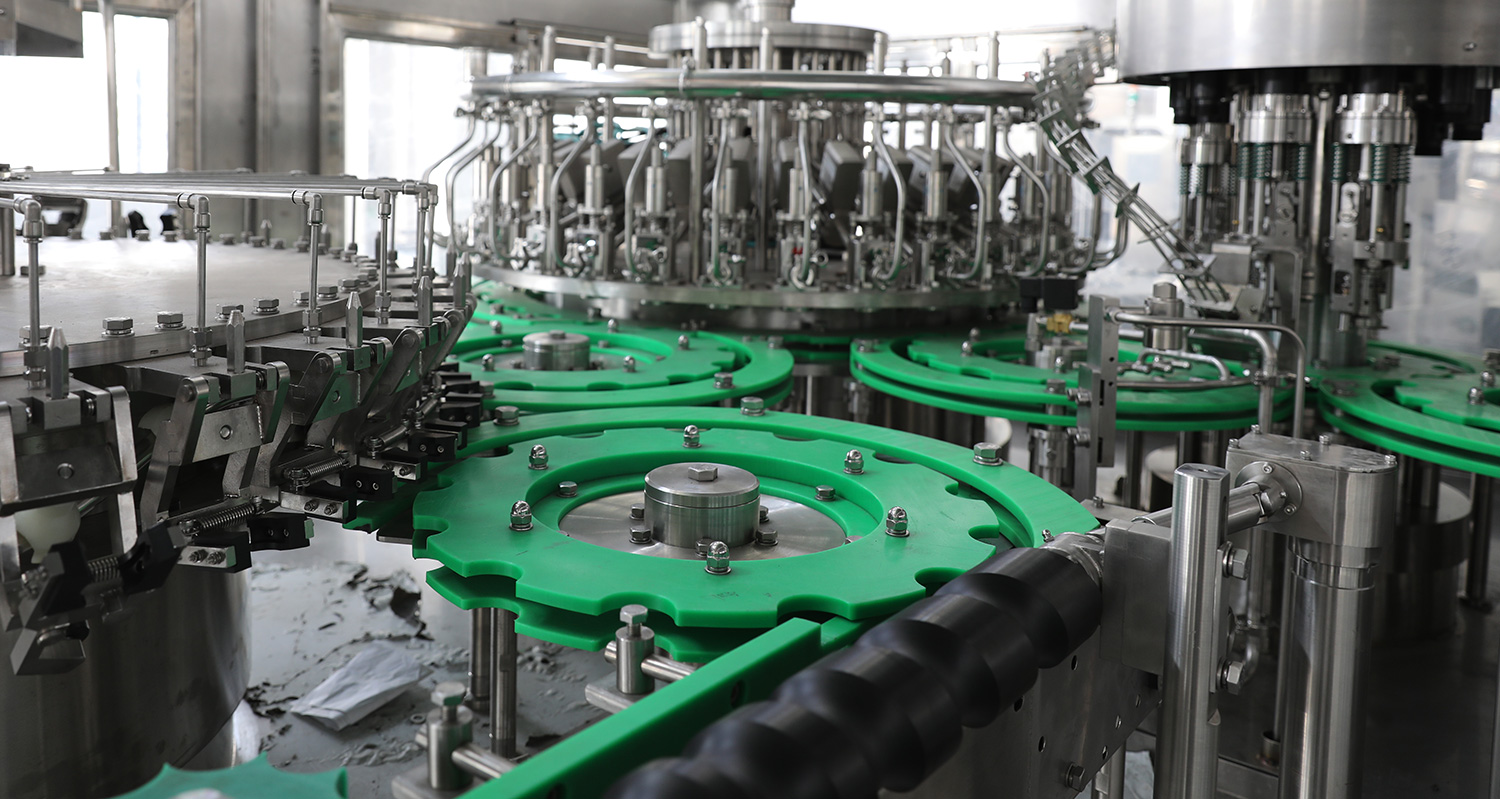

Automatic Bird nest filling machine with high production

It is suitable for filling and seaming non-carbonated liquid such as water, juice, functional beverage, etc. It is equipped the advanced device, electrical equipment, and pneumatic control technology. It has the characteristics of filling reposefully, high speed, liquid level control, seaming reliably, frequency conversion timing, less material loss. It is the preferred equipment for beverage plants.

- Wholly sealed widow structure which is beautiful, concise, easy and highly operated;

- Producttank design with precision polishing inside;

- High precision and large flow rate filling valves to meet productive requirement;

- Specially designed roller structure which is easy to be adjusted, locked and ensure sealing function;

- Friendly and convenient operating panel with high expansibility.

Working Procedure

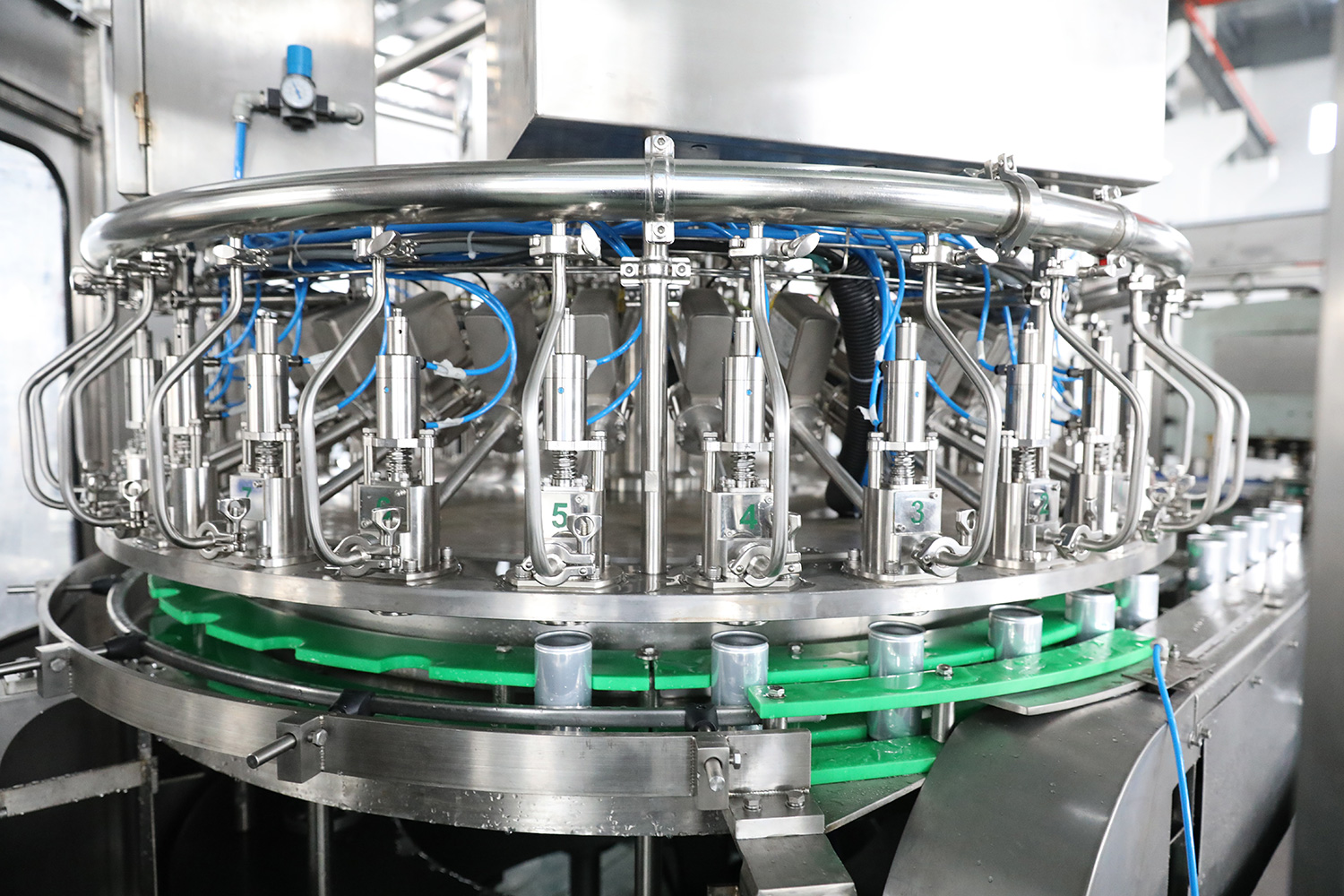

Cans will be pushed into can holding platform one by one by feeding screw and star-wheel. Centering cup of filling valve will fall to can; the distance between filling valves and cans is sealed by springiness plastic ring. The movement of centering cup is generated by plastic idler wheel along curvilinear motion. After filled, valve will be closed and centering cup will rise from the can. Filled can will be sent to conveyor chain, then to seamer. Seamer will take lid, turn over the edge of can and turn the edge to finish the sealing action by the control of cam. After that can will be transferred to conveying system.

Can Infeed

Combination of infeed screw and starwheel.

Filler by electromagnetic flowmeter

Seamer

Can Outfeed

Nylon wheel and conveyor belt cooperate output cans. Conveyor motor uses frequency control of motor speed, which keeps pace with the 2-1 machine.

Rack part

Rack is welded by high quality carbon steel, Antirust processing and spray surface. The surface is covered by the SUS304.

Electronic control system part

The electronic components like PLC and transducer are from Mitsubishi, Omron, etc., The pneumatic devices are also from international famous brand.

Equipment structure

- Rack

- Rotary filler

- Rotary seamer

- Aluminuminfeed and outfeed system

- Control

Main Electrical Specification

- Touch screen:Mitsubishi

- PLC program controller: Mitsubishi

- Inverter: Mitsubishi

- Low-volts breaker: Schneider

- Photoelectricalcontroller: Sick

- Proximity switch: Sick

- Contactor: Schneider

Technical Parameter

Model: RYGF18-4

- Filling head: 18

- Seaming head: 6

- Capacity: 9,000 cans/hour(330ml)

- Filling valve center diameter: φ576mm

- Filling valve pitch: 32π

- Can diameter: φ53-66mm

- Can height: 85-140mm

- Conveyor height: 1250-1400mm

- Motor power: 3kw

- Dimension: Filler 1860×2900×2180mm; Seamer 2650×1800×1240mm

- Weight:Filler 1800kg; Seamer 2270kg

RYGF24-6

- Filling head: 24

- Seaming head: 6

- Capacity: 24,000 cans/hour (330ml)

- Can diameter: φ50-80mm

- Can height: 90-170mm

- Motor power: 4.23kw

- Dimension: 2600×1380×2000mm

- Weight: 3000kg

Model: RYGF30-6

- Filling head: 30

- Seaming head: 6

- Capacity: 18,000 cans/hour(190ml)

- Filling valve center diameter: φ576mm

- Filling valve pitch: 32π

- Can diameter: φ50-99mm

- Can height: 39-160mm

- Motor power: 5kw

- Dimension: 2750×1750×1900mm

- Weight:5000kg

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg)