Can filling line for carbonated energy drink and alochol drink filling machine

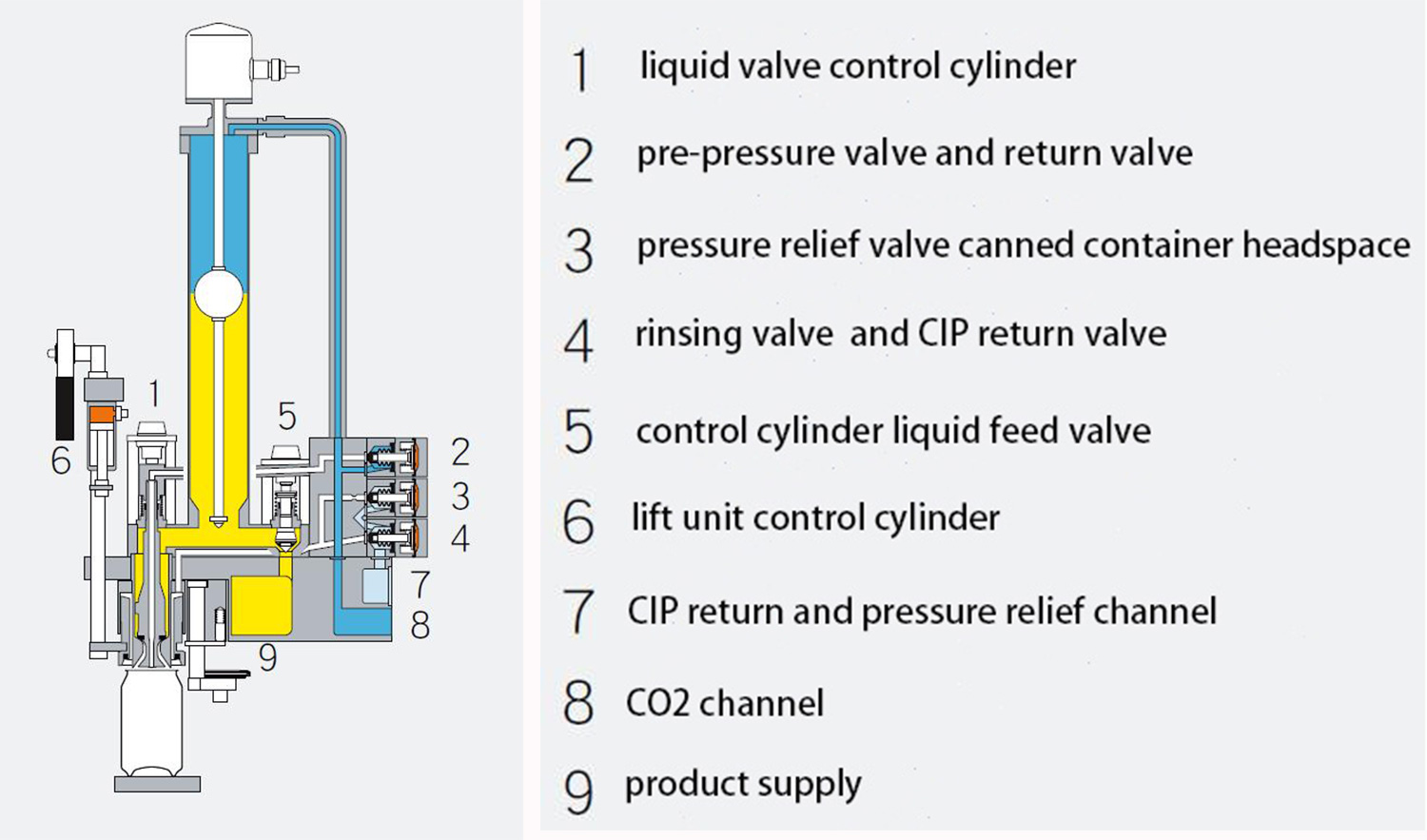

It is suitable for filling beer or beverage which contains CO2, (such as carbonated juice, beer, etc.), also non carbonated drinks like juice, tea, drinking birdnest, etc. It is equipped with float ball cylinder electrical pneumatic valve, which is also the world’s advanced technology for carbonated and non carbonated canning filling. It adopts float ball cylinder quantitative filling and the electrical valve controls the filling capacity to be constant during filling process.

The working principle of this machine is as follows. First, the washed empty cans enter the filling cylinder through the infeed screw and star wheel. After pressed and sealed under the centrifugal cover, the cans are rinsed with CO2, and start filling after the cans are left for a while to stand still. The filling is performed in rapid filling and slow filling in turn. After finishing filling, stand still for a while and then perform slow and fast discharging in turn. The centrifugal cover lifts after exhausting completely, then the finished cans discharge from filling cylinder and enter the conveyor belt. The cans enter the sealing machine by foam purge driven by chain fork. The capping head of the sealing machine rotates and keeps the revolution. The capping head presses the can with the lid and rotates. Turn over the edge of can and turn the edge to finish the sealing action by the control of cam. The sealed cans are transferred to conveyor system through the discharge star wheel.

Main features

(1) High filling accuracy

- Float ball measuring cylinder is used for quantitative volume, high filling accuracy;

- High accuracy of aeration control.

(2) High degree of intelligence

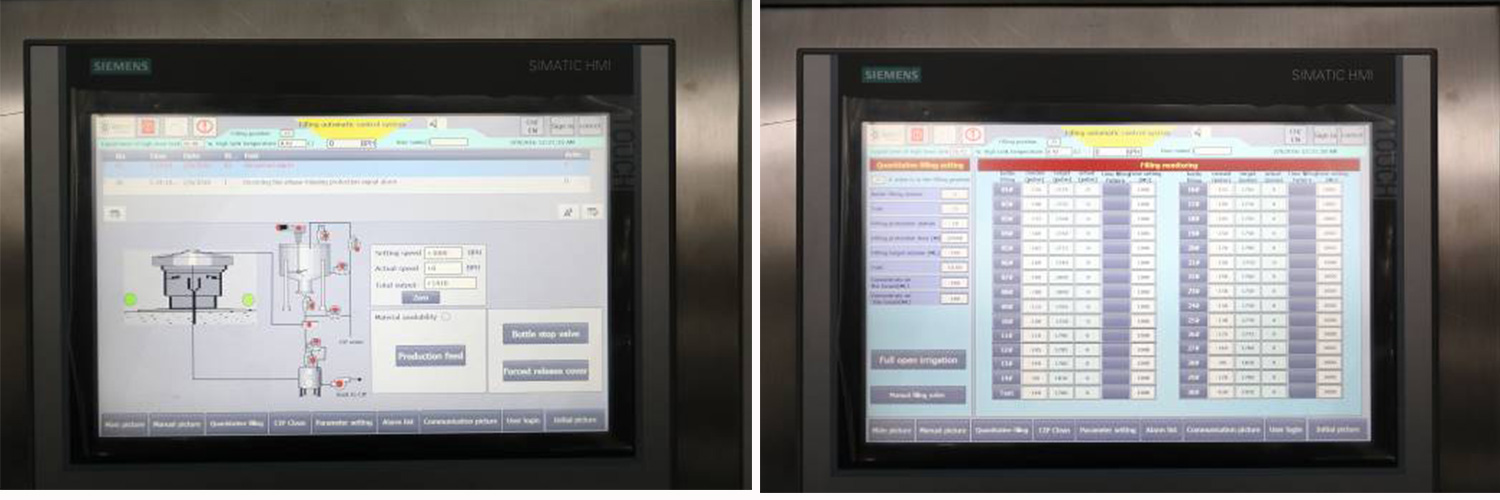

- Filling capacity can be adjusted in-line without stopping, can be adjusted as a whole, or can be adjusted with a single valve;

- Filling steps can be set: it can set the replacement or not, or the replacement time, it can set the water blowing or not, or the water blowing time, it can set the filling station;

- The recipe can be pre-stored. For a certain can type or a certain liquor variety, the recipe which has been set can be pre-stored and directly blending in the next production;

- Pump beer or products, CIP automatic control.

(3) High humanize

- Short changeover time, electric lifting, no need to replace mechanical parts (only when can height is changed);

- Filling time, supplying time, and cylinder filling are real-time displayed on the touch screen;

- Production status can be monitored remotely.

(4) Low cost

- Low cost of spare parts, less wear parts, only one mechanical cam;

- The equipment has a high degree of automation which saves staff.

(5) Others

- The whole appearance is beautiful and easy to clean. All the parts above the platen are made of stainless steel, which has good corrosion resistance;

- The machine is equipped with cleaning cup. The greater pressure the cleaning cup bears, the better sealing performance, it is easy to install and with good sealing performance;

- Safety: The equipment is equipped with a series of safety devices and safety protection.

(6) Sealing part

- Sealing roller is the original Taiwan roller with high hardness alloy steel quench (HRC> 62). The sealing curve is precisely processed by optical curve grinding to ensure the sealing quality and ensure the normal operation of the machine;

- At the lid-feeding tray of the can sealing machine, before the mouth and the lid of the can are not attached, CO2 blows the inside of the can through air blower to drive the air in the upper part of the beverage in the can to achieve the purpose of deaeration until the mouth is completely sealed with the lid;

- The machine has capping with can, no capping without can control system, to ensure the normal running of the machine and reduce the cap loss rate;

- The aluminum cap is manually placed in the chute and lowered by the cap gravity and thruster. A detection switch is equipped in the chute to ensure that the machine can stop when lack of caps;

- Depending on the tank type at different heights, the sealing machine can be lifted manually to meet the requirements according to cans type with different height.

Can Infeed

-

Cans divide into fixed intervals through screw to can infeed dial wheel, then enter into filling machine. After filling, cans are transported to the capping machine through the tank device. By two curling, capping is completed. Cans are sent into the can outfeed dial wheel and transmitted to can outfeed belt, then sent to the next process (or equipment).

Filler

Filling machine components mainly consist of filling cylinder, turntable, volumetric filling valve, lifting devices, upper and lower distributor, star wheel device, screw transmission device and main liquid pipe, etc.

CO2 flushing before filling to control oxygen increase (≤30ppb); using high pressure foam flushing system to remove air on upper part of can before seaming.

Seamer

-

Can sealing machine mainly consists of the upper part of the machine, the lower part of the machine, under the cover device, motor drive, hydraulic system and other components.

This model type of sealing machine with a filling machine drive, The cans coming out from the can outfeed dial wheel of the filling machine are infed in a free order at the beginning and through a period of chain acceleration to make the tank reach the correct pitch feed tank side belts, in order to prevent the overflow of the liquid in the tank, the tank must have a certain range of adjustment for the delivery of the dial on the side belt of the tank. When each can passes through the canister to detect the proximity switch, the proximity switch is actuated. At this time, the cylinder (makes the lid cutter on the lid retract, a can lid is removed from the lid stack, and is carried by the lid transfer turret under the capping head, before the cap can reach the capping device together with the cap, the cap can be accurately positioned through the cap transfer and the sealing star wheel swivel, and then when the cap arrives, the cap supporting platform accurately lifts the can to the cap’s position.

At this moment, the lid is pushed by the lid to press the lid onto the top of the tank. When the can is clamped between the tray can holder and the capping head, the lids start to rotate together, and the capping operation begins. Two flanging rollers complete the crimping.

The lid rod pushes the can away from the capping head, and at the same time, the tank star wheel pushes the sealed cans out of the can sealer and puts the cans onto the conveyor belt of the can table.

Hydraulic system of can sealing machine

Hydraulic system of can sealing machine mainly realize the lifting of the rack of can sealing machine. The hydraulic includes manual hydraulic pump, reversing valve and two working oil cylinders.

Manual hydraulic pump is the power source, when operating, the manual force acts on the pressure rod to drive the plunger to reciprocate, and generates the pressure of the oil. The pressure oil enters two working oil cylinder at the same time through the reversing valve. When asked the rack to lift, the pressure oil enters the bottom of working cylinders through the reversing valve, to promote the piston of cylinder move upward, the rack also slowly rises to reach the required height, if the direction of the reversing valve is changed, the rack will fall automatically.

Can Outfeed

Nylon wheel and conveyor belt cooperate output cans. Conveyor motor uses frequency control of motor speed, which keeps pace with the 2-1 machine.

Rack part

Rack is welded by high quality carbon steel, Antirust processing and spray surface. The surface is covered by the SUS304.

Control System

The electronic components like PLC and transducer are from Mitsubishi, Omron, etc., The pneumatic devices are also from international famous brand.

Equipment structure

- Rack

- Rotary filler

- Rotary seamer

- Aluminum infeed and outfeed system

- Control

Main composition

- PLC Siemens or Mitsubishi

- Main motor ABB

- Pneumatic component Airtac or SMC

- Touch screen Siemens or Proface

- Inverter Siemens or Mitsubishi

- Filling level electrical float ball Balluff

- Breaker Siemens or Schneider

- Contactor Siemens or Schneider

- Main bearings NTN

- Proximity switch Leuze

- Photoelectric switch Leuze

- Lubrication bearing Igus

- Seal Sealtech

Technical parameters

Model: YDGF20-4

- Rated capacity: 12,000BPH(330ml)

- Can height: 80-135mm

- Can diameter: ф45-ф70 mm

- Applicable can type: aluminum can(200, 202, 206, 209 need to change)

- Applicable lid type: standard aluminum cap

- Filling head: 20

- Filling temperature: 0-4℃

- Speed of filling valve: 140-150ml/s

- Sealing head: 4

- Motor power: 3KW

- Consumption of CO2: 120g/hl

- Consumption of compressed air: 05m 3/min(0.6MPa/hr)

- Dimension: 3600×1960×2450mm

- Weight: 3500Kg

Model: YDGF24-6

- Filling head: 24

- Seaming head: 6

- Capacity: 12,000 cans/hour (300ml)

- Can diameter: φ50-80mm

- Can height: 90-170mm

- Motor power: 4.23kw

- Dimension: 2600×1380×2000mm

- Weight: 3000kg

Model: YDGF30-6

- Capacity 18,000BPH (500ml)

- Filling heads 30 pcs

- Seaming heads 6 pcs

- Filling method Isotonic filling

- Filling temperature 0-4°C

- Chain space 4mm

- Conveyor height 1200-1400mm

- Size 4265×2700×2450mm

- Weight 5000kg

- Can diameter 45-70mm

- Can height 80-175mm

- Power 26KW

- Compressed air 5Nm3h(0.6MPa)

Model: YPGF36-6L

- Capacity 15,000BPH (500ml)

- Filling heads 36 pcs

- Seaming heads 6 pcs

- Filling method Isotonic filling

- Filling temperature 0-4°C

- Chain space 4mm

- Conveyor height 1200-1400mm

- Size 5265×2700×2450mm

- Weight 5300kg

- Can diameter 45-70mm

- Can height 80-175mm

- Power 9KW

- Compressed air 5Nm3h (0.6MPa)

Model: YDGF40-6

- Capacity 24,000BPH (330ml)

- Filling heads 40pcs

- Seaming heads 6pcs

- Filling method Isotonic filling

- Filling temperature 0-4°C

- Chain space 4mm

- Conveyor height 1200-1400mm

- Size 6500×2700×2450mm

- Weight 7000kg

- Can diameter 45-70mm

- Can height 80-175mm

- Power 10KW

- Compressed air 08m3/h (0.6MPa)