15000bph 1L High-Capacity Glass and Plastic Pet Bottle Olive Oil Rotary Filling Machine

XGFY series 4-in-1 filling machine equipped with rotary transmission, which consist of bottle infeed screw, gas rinser, weighing filler, screw capper , press capper, finished bottle discharge chain, sealed window, electrical control box, etc.

System composition: According the process requirement,the system is mainly divided into rinse the bottle(gas), filling and capping system, electrical control system, etc.

1.4-in-1 oil filling machine are mainly composed of main drive, rinsing, filling, capping, star wheel, including 50 heads of

rinsing, 50 heads of filling, 12 heads of aluminum screw cap and 10 heads of plastic press cap.

2.The equipment adopts self-developed weighing non-contact filling device, and the filling method is rotary filling, in which

includes feeding equipment, servo motor control valve opening, dynamic weighing detection device and PLC control

3.The analog controlsthe opening of the filling valve can accurately control the filling flow rate and fluid leve

4.Filling according to dynamic weighing, and it cancontrols the size of the valve opening after accurate measurement.

5.The device uses a sanitary valvefor fast response.

6.The contact between the equipment and the finished product (pipeline, filling valve) is made of SUS304 material, which meets the requirements of food machinery.

7.The equipment adopts screw way to feedthe bottle, star wheel drive, and screw drive is designed with overload detection device.

8.Equipped with human-machine interface, PLC control system and touch screen control.

Detailed Images:

-

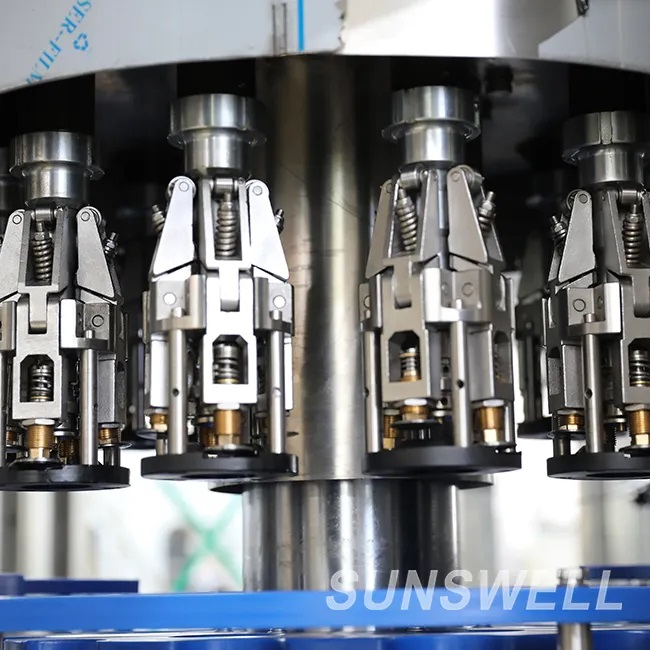

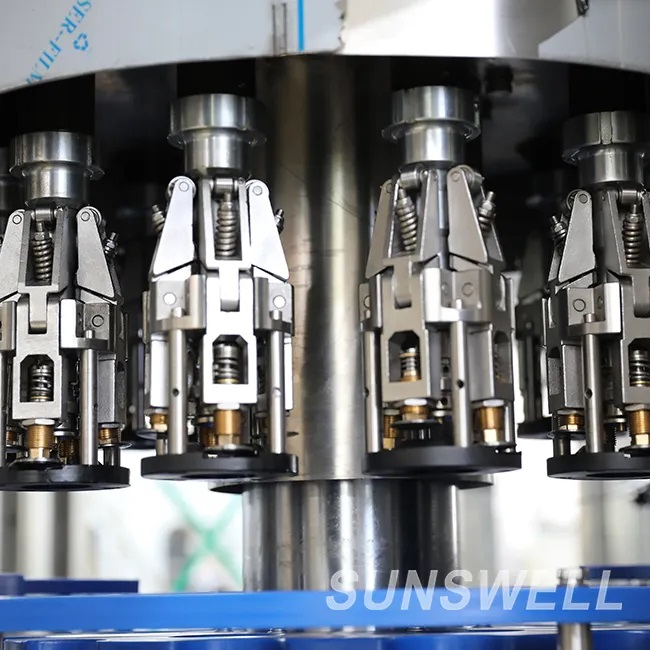

Rinser

-

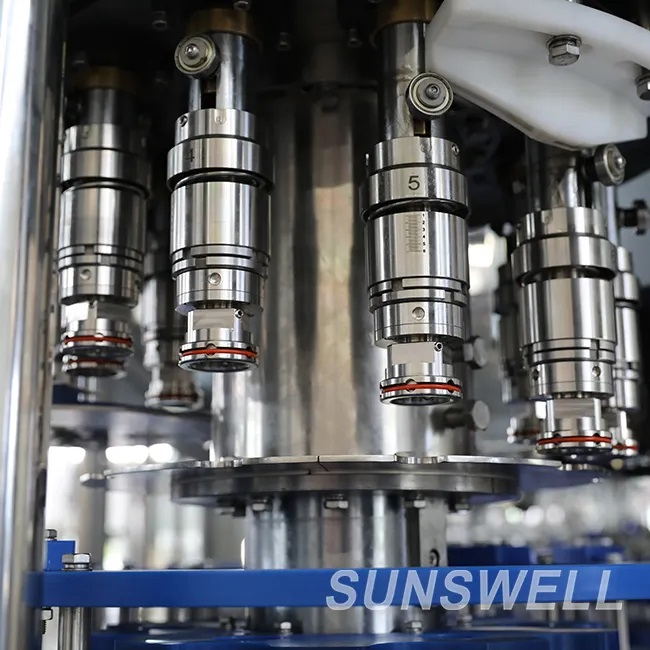

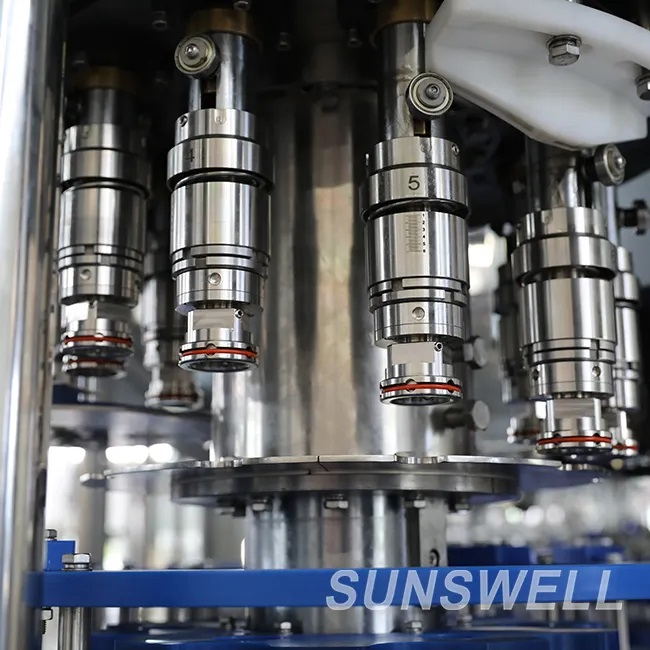

Weight filler

-

Aluminum cap screwing machine

-

Plastic press capping machine

Main Features

1.Empty bottle screw variabledistance transmission, which can be changed according to the requirement of customer.

2.Filling using dynamic weighing measurement,accurate filling weight, stable operation of Equipment.

3.Filling weight can be adjusted according to customer requirement.

4.Equipped with centralized refueling device, which can save refueling maintenance time.

5.The height of the rinser,filler,screw capperand press capper can be adjusted according to the customer's bottle shape with strong applicability. The adjustment power is domestic motor.

6.Capping head with pressure scale can be customized.

7.The capping machine puts the cap accuratelyand screws the cap stably. No bottle,no cap.

All stainless steel welded rack, which is covered with stainless steel mask.

Technical Parameters

|

Model |

XGFY50-50-12-10 |

|

Station number |

50 heads of rinsing, 50 heads of filling, 12 heads of aluminum screw cap,10 heads of plastic press cap. |

|

Production capacity |

15000BPH(1L) |

|

Filling system |

Weighing non-contact filling |

|

Applicable bottle type |

Diameter;φ50-φ120mm, Height;165-290mm |

|

Gas consumption |

About 1.3m³/min |

|

Rated voltage |

440V,60HZ,three-phase five-wire |

|

Main motor power |

About 11kW |

|

Elevation(bottom of bottle to ground) |

About 1150mm |

|

Dimensions |

About 6500×4300×3200mm (length×width×height) |

|

Weight |

About 15000Kg |

Main Configuration

|

No. |

Item |

Configuration description |

|

Bottle infeed screw |

||

|

1. |

Screw material |

ultra-high molecular polyethylene |

|

2. |

Screw dive |

gear drive with safety clutch Brand:Nangjing gongnuo |

|

Transmission star wheel |

||

|

1. |

Bottle contact star wheel guide plate |

ultra-high molecular polyethylene,height;About20mm |

|

2. |

Bottleboard |

material 304, thickness≥6mm |

|

Bottle rinser |

||

|

1. |

Rinse clamp |

(1)The material is 304, and the bottle clamp is ultra-high |

|

2. |

Rinsing medium |

(1) Gas flush bottle |

|

3. |

Other |

(1) Rinse clamp mounting tray material:304 |

|

Filler |

||

|

1. |

Liquid tank |

(1) Material304,bottom plate≥16mm |

|

2. |

Filling valve |

(1) Valve opening executive motor:IGUS |

|

3. |

Rotary pneumatic solenoid valve |

Brand:FESTO or SMC |

|

Aluminum cap screwing machine |

||

|

1. |

Screw cap head |

(1) Capping head is aluminum, made in China |

|

2. |

Cap scraper |

(1) Installed above the filling capping wheel |

|

3. |

Integral component |

(1) Screw cap with bottle bottom plate |

|

Plastic press capping machine |

||

|

1. |

Press cap head |

(1) Screw cap head is visible on the outside and made of |

|

2. |

Shift cap tray |

(1) Installed on the side of the capping machine |

|

3. |

Integral component |

(1) Screw cap with bottle bottom plate |

|

Cap supply system |

||

|

1. |

Aluminum cap supply system |

(1) Waterfall lid lifter |

|

2. |

Plastic cap supply system |

(1) Cap through the belt |

|

Window sealing rack |

||

|

1. |

Main rack |

(1) Stainless steel 304 welded construction |

|

2. |

Window sealing |

(1) Closed,flushing area has a fan for air extraction,filling and |

|

Other major configuration |

||

|

1. |

Main electric control cabinet |

Material:304,drawing block |

|

2. |

Electric appliance configuration |

(1) PLC:Siemens or equivalent brand |

|

3. |

Other |

(1) Plastic bearing brand;IGUS |