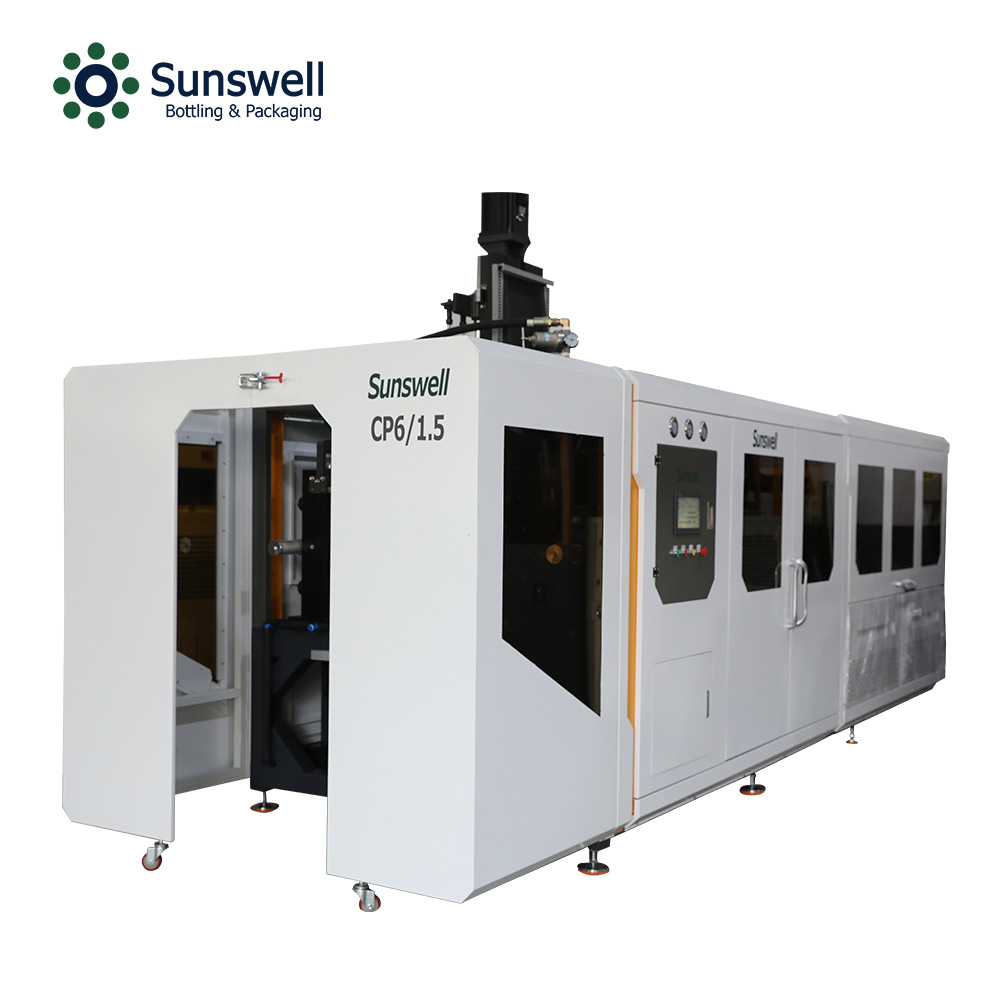

12000bph 350ml square juice bottle stretch blow molding machine

This JCR-6US series model of fully automatic rotary heating stretch blow molding machinery is specially designed for high speed based on absorbing all international latest technology, it is an economic two stage automatic stretch blow molding machine, mainly used for PET stretch blow bottles. The machine consumes less power due to optimized machine layouts and patented preform heating system, so the end of user can achieve maximun profit in today's competitive bottle molding market.

Preform feeding system

Single-channel preform feeding and star wheel preform feeding , which effectively solves the problem of jamming and wear between

preforms and preforms.

Revolution system

Special chains are used, driven by servo motors, so that the heating unit moves smoothly, fast in positioning and low in noise

Mold system: adopts high-pressure mold clamping technology, no mold expansion phenomenon, and the mold clamping line is thin.The mold adopts a drawer structure, positioned on the mold back plate with four fixed tie rods, and can be easily replaced within half an hour.

Stretching and blowing system: the cycle time of first blowing and second blowing can be adjusted, and each tie rod can be adjusted independently according to different tube blanks and different bottle types of customers, with high flexibility.

Electric control system: Pneumatic and electrical components are all international famous brands. The touch screen control system is easy to operate, has perfect monitoring and induction settings, has fault diagnosis function, automatic calculation report function, and grasps the production efficiency of each shift.

Cooling/chilled water circulation system: There is a cooling water channel under the heating box, and the cooling water channel is used to block the heat of the lamp tube when the preform is heated, so as to protect the teeth from deformation. Chilled water leads to the mold to quickly cool the mold and improve the production efficiency of the whole machine

Main Configuration

|

Component name |

Origin |

Brand |

|

Electrical/Control Components |

||

|

Air switch |

France |

Schneider (TE) |

|

Intermediate relay |

Japan |

Omron ( OMRON ) |

|

Contactor |

France |

Schneider (TE) |

|

Button |

France |

Schneider (TE) |

|

Control switch |

France |

Schneider (TE) |

|

Magnetic switch |

Taiwan |

AIRTAC |

|

Touch screen |

Taiwan |

Delta (DELTA) |

|

Motion Controller |

Taiwan |

Delta (DELTA) |

|

Servo |

Taiwan |

Delta (DELTA) |

|

Cylinder |

Taiwan |

AIRTAC |

|

Valves/Fittings |

||

|

First blow valve |

U.K. |

Norgren |

|

Second blow valve |

Norgren |

|

|

Vent |

Norgren |

|

|

Cylinder control valve |

Taiwan |

AIRTAC |

|

Clamping rail |

South Korea |

WON |

Technical Parameters

|

Composition |

Project |

Technical Parameters |

|

Product conditions |

The largest diameter of the product (mm) |

Φ103 |

|

Product bottle size (mm) |

Φ18 ~ Φ38 |

|

|

The maximum height of the product (mm) |

<340 |

|

|

Suitable for rpeform maximum height (mm) |

<165 |

|

|

Clamping stroke (mm) |

125 |

|

|

Bottom mold stroke (mm) |

50 |

|

|

Bottle spacing mmM) |

110 |

|

|

Production capacity (bottle/hour) |

8000-90000BPH(1.5L) |

|

|

Production capacity (bottle/hour) |

15000-16000BPH(550ML) |

|

|

Number of mold cavities |

|

|

|

Heating part |

Heating unit |

6 |

|

Layers of heating lamp |

8 |

|

|

Number of germ tube seats (pieces) |

156 |

|

|

Electrical parameters |

Voltage |

380V |

|

Frequency |

50/60Hz |

|

|

Use power |

30-40kw/h |

|

|

Installed power |

100kw |

|

|

Gas source |

Low pressure compressed air |

1Mpa |

|

Low pressure compressed air consumption |

1.0m³/min |

|

|

High pressure compressed air |

3.0Mpa |

|

|

High pressure compressed air consumption |

10 m³/min |

|

|

Cooling water |

Pressure |

2-4bar |

|

Cooling water (water temperature ≤18°C) |

Flow |

6m 3 /h |

|

Weight |

Host \ heating machine \ electric control box, etc. |

about 7.5 t |

|

Equipment Dimensions |

Host (L × W × H) |

5000mm×2300mm×2900mm |

|

Preform unscrambling machine (L×W×H) |

2950mm×2120mm×3200mm |