-

tel:

+8613921964455 -

Email:

info@sunswell.com

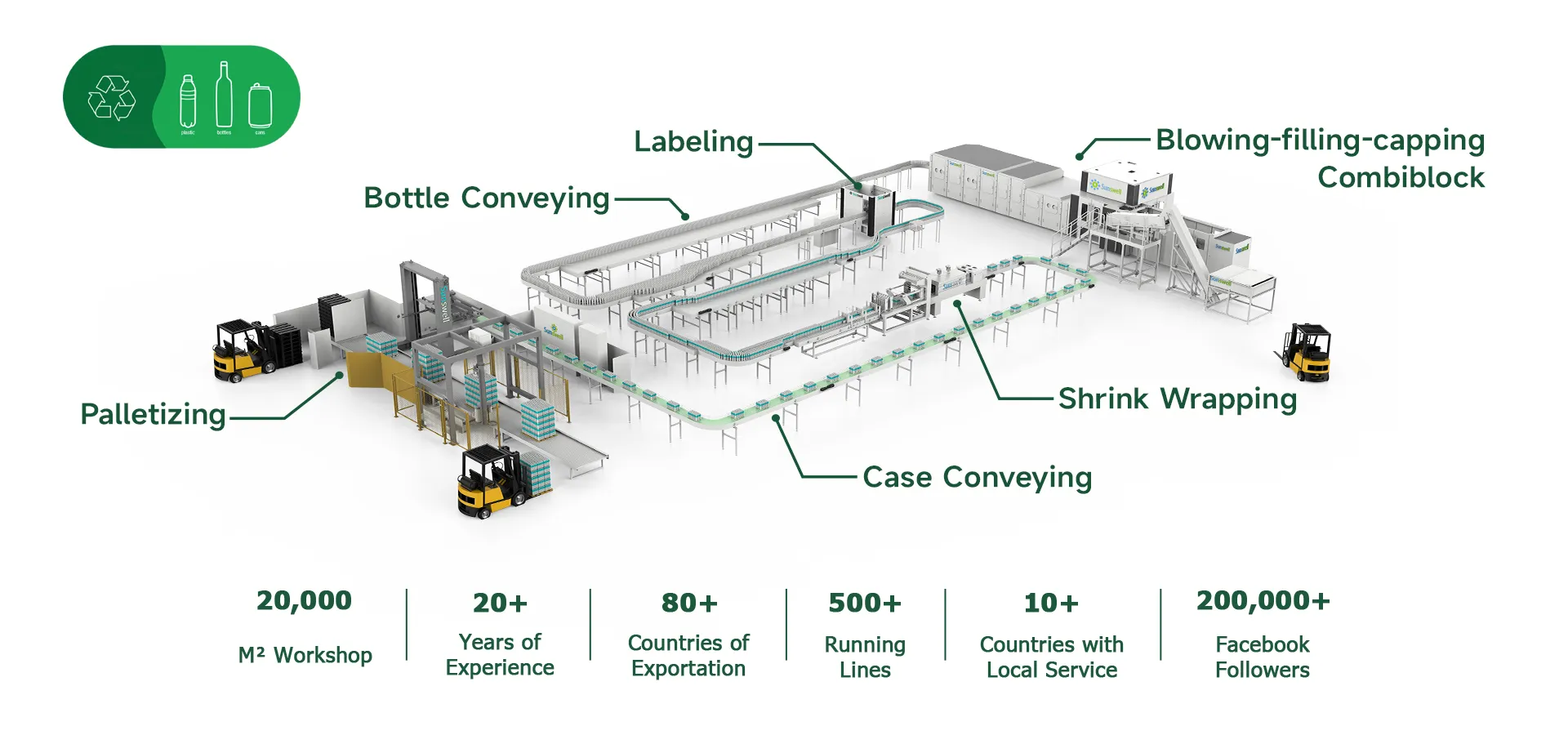

Turn-key Plant

Leadership in quality and technology from raw material to bottled liquid to selling products - Sunswell, A-Z turnkey plant supplier, is known for developing innovative high-end products and new technologies.

Beverage Machinery

Leadership in quality and technology from raw material to bottled liquid to selling products - Sunswell, A-Z turnkey plant supplier, is known for developing innovative high-end products and new technologies.

Blow Molding

Enjoy our most advanced auto PET bottle moulding

machines applied in multiple industries with

different models and esp. low energy

consumption.

Bottle Filling

Enjoy our most advanced auto PET bottle

moulding

machines applied in multiple industries

with different models and esp. low energy

consumption.

Labeling

Enjoy our most advanced auto PET bottle

moulding

machines applied in multiple industries

with different models and esp. low energy

consumption.

Packaging

Enjoy our most advanced auto PET bottle

moulding

machines applied in multiple industries

with different models and esp. low energy

consumption.

Customer Stories

Still have some hesitations whether cooperation with us is worth the trouble? Check the reasons why you should choose us among other companies!

Customer Information

Country: Maldives

Product: PET Bottled Mineralized Water

Capacity: 24,000BPH (500ml); 2 Lines

Customer Information

Country: Kazakhstan

Product: PET Bottled Sparkling Water, Canned Soft Drink, Canned Tea

Capacity: Three Lines; 7000BPH(1.5L); 18000CPH(330ml); 18000CPH(450ml)

Customer Information

Country: Syria

Product: Aluminum Canned Carbonated Soft Drinks

Capacity: 25000CPH (250ml)

Customer Information

Country: Turkey

Product: Glass and PET Bottled Juice

Capacity: 20000BPH(330ml) Glass Bottle; 4000BPH(3L) PET Bottle

SUNSWELL WILL DO MORE AND MORE

We provide a wide range of services to meet even the most daring requirements

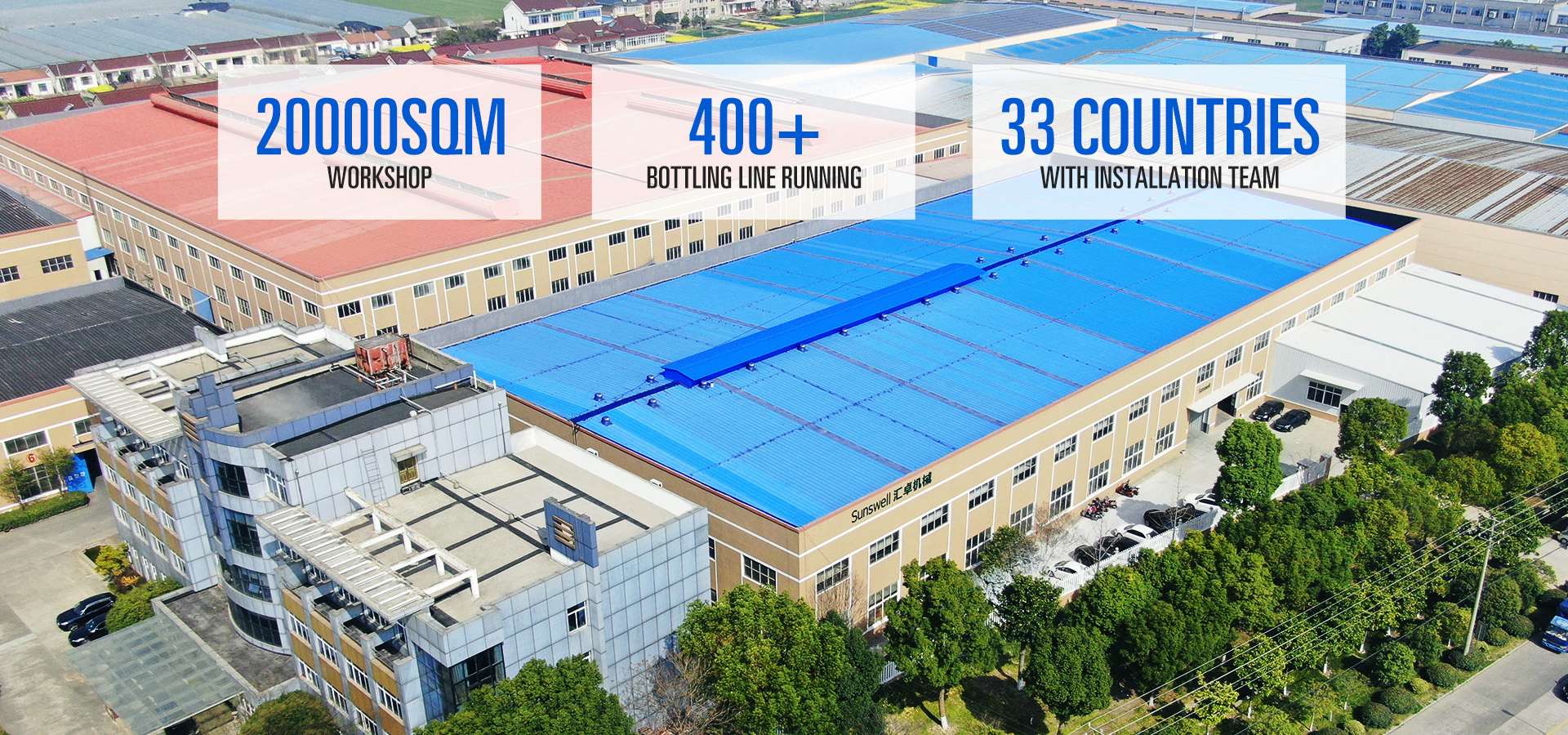

2008

Set up in 2008, We have rich industry experience

20000+

The factory covers an area of 20000 square meters

20+

professional and technical personnel

Set up in 2008, Sunswell leads the market in the field of liquid bottling, blow molding, labeling, packaging machinery and process technology for water, tea, juice, carbonated drinks, energy drinks, liquid, beer, edible oil, dairy and daily care products, etc.

We can customize liquid food production lines according to customers’ demand. Every customer is the result of our proven experience and innovation. We continually focus on providing customers with advanced technology, engineering and facility that are designed with one motto in mind: ensure you to reach business goals with most optimized planning.

Latest News & Articles